Scenic Fruit Case Study

Challenge – Scenic Fruit Company of Oregon, is one of the Pacific North West’s premier berry processors. The increase in labor cost and food safety regulations were having a negative effect on profit margins. Bins of fruit weighing over 300 lbs come out of the field needing dumped in to a water tank and then the bins got hand washed before returning to service. Our challenge was to automate this process removing the need for excess labor and cutting down on fork lift traffic. Desire result:

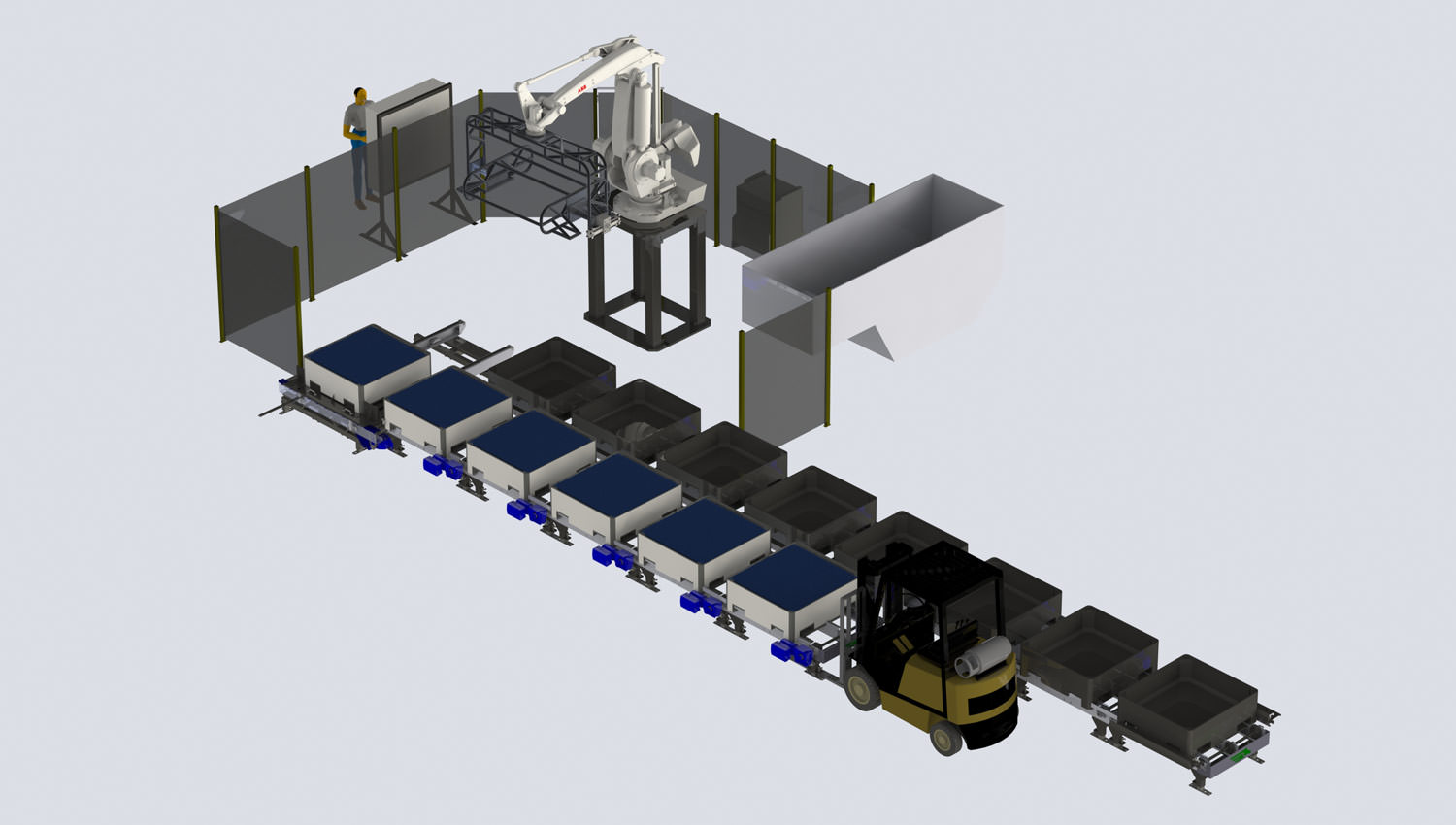

Solution – In order to maintain the highest level of food safety the line needed to be wash down. So we designed and built stainless steel infeed conveyors to handle 5-8 stacks of 5 high bins. Each stack weighing as much as 1 ton. An ABB 760 robot then de-nested the bins then gradually and smoothly dumped the berries into a water tank. The robot then inserted the 48”x48” plastic bin into a wash system and paused while the bin was sanitized. The robot then withdrew the bin, righted it and re-nested it on out-bound stainless steel conveyors. They robotic system out-paced their existing processing line requiring the robot to be “turned down” to slow its pace. Needless to say the objectives were met and exceeded.

Join Our Mailing List