Scratch and Peck

Challenge – Scratch and Peck Feeds, a national leader in high end natural animal feeds had to expand. Sales exploded and their existing mill could not keep up. As part of a completely new mill Byron Automation was challenged with not only the palletizing portion of the line but the in process as well. Feeds needed to be bagged direct from a blending tank or from one of two other storage bins. The feed needed to be conveyed loose, weighed, bagged, tagged and conveyed to the robotic palletizer. Goals:

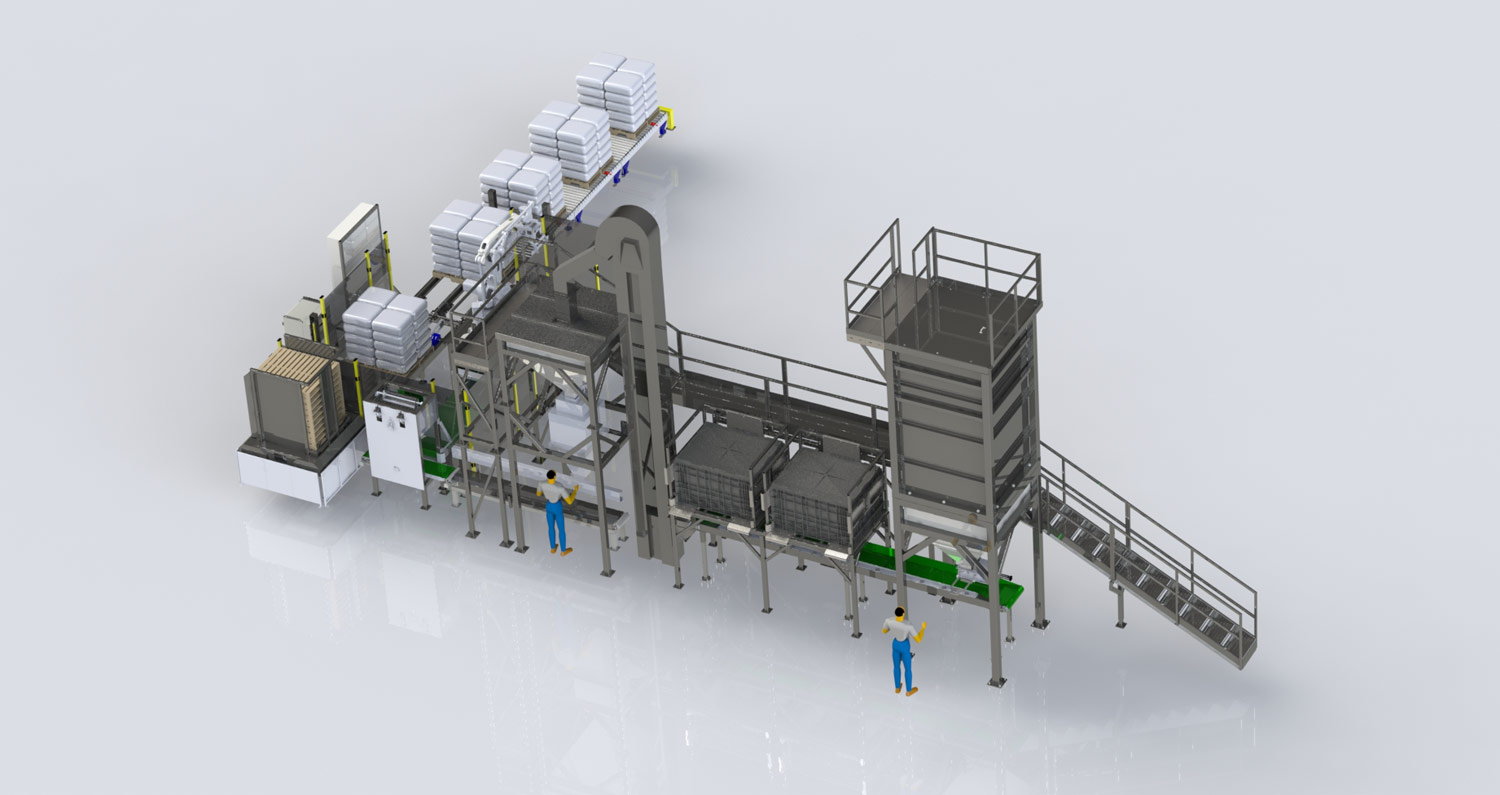

Solution – Working collaboratively with the manufacturer of the milling equipment and the general contractor of the new building; Byron engineered, built and installed a solution to meet all of the project goals. The solution included elevated bin stands with PLC controlled gates and loose product v-trough conveyance. The v-trough fills a bucket elevator feeding the receiving hopper from the blending tank. An inline net-weigher fills the bags and an automatic sewing line closes the bag and attaches a sewn in tag.

Join Our Mailing List