Marion Ag Services

Challenge – Located in Oregon, Marion Ag Services is an ever growing supplier of both commercial and residential fertilizer. With an increase in demand for their product they knew they needed to expand. With soaring labor rates, they knew they needed to automate. Marion Ag built a new facility with state of the art blending equipment and a full robotic compliment from Byron Automation. One of the critical aspects of the project was on the material handling side. For adequate warehouse buffering they need a lot of pallet accumulation but additionally they wanted to trim labor and cost out of weather protecting (manually placed rain hoods) and load stabilization (stretch wrapping). Their unimproved process meant sometimes triple handling their pallets. Goal:

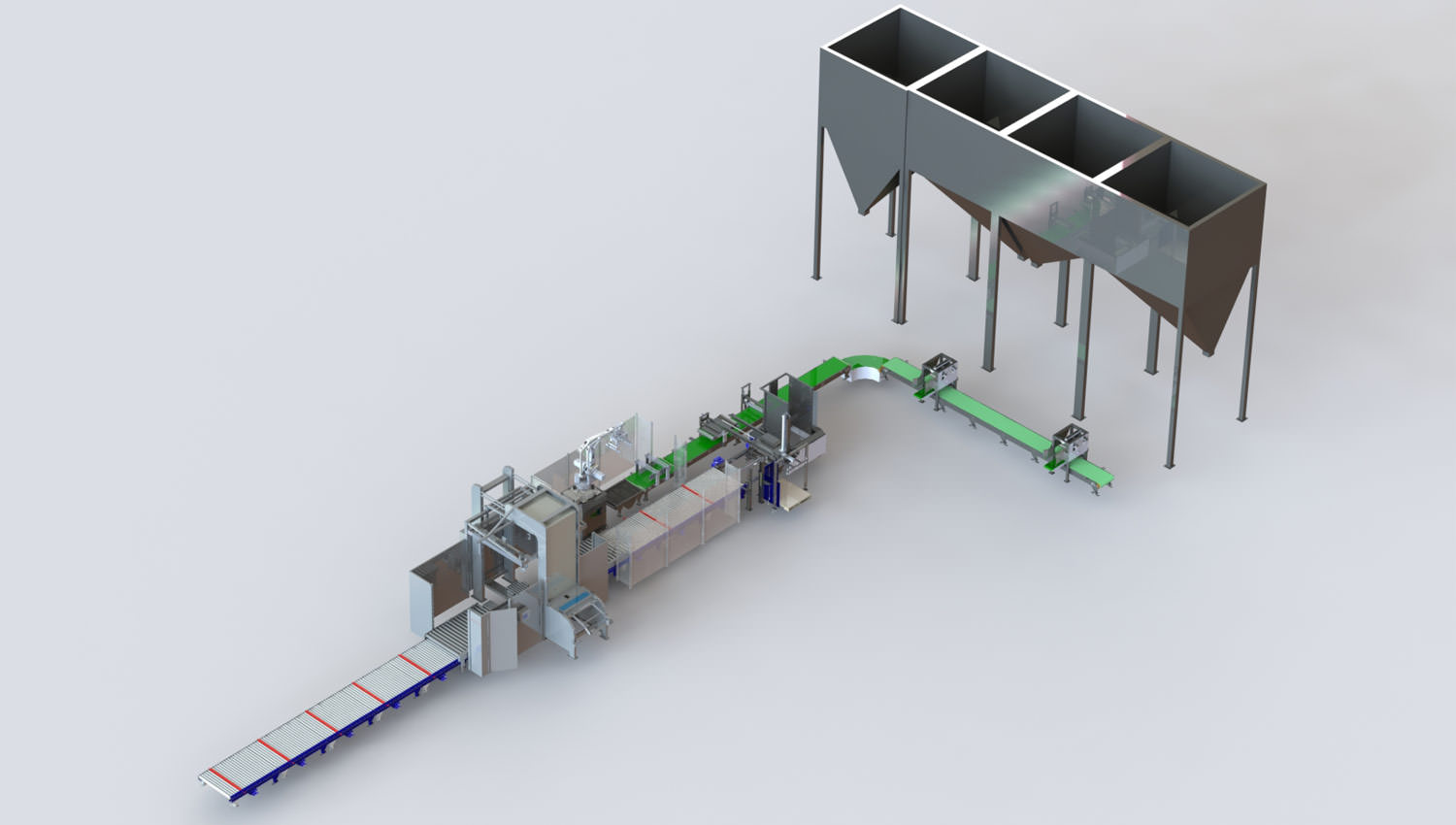

Solution – The pallet accumulation was the easy part. We built a system consisting of smart conveyance to stage and buffer pallets. This would allow for maximization of labor efficiency in the warehouse. The trickier part was the load prep cost/labor reduction. Byron in collaboration with their global partners built the Dino –Stretchhooding solution. This solution ultra sonically measured the pallet and custom made a weather tight stretch hood eliminating the need for stretch wrap and a rain hood. This resulted in a complete elimination of the previous labor positions while providing a 30% decrease in material cost. The automated material handling solution is capable of processing 100 pallets and hour making faster than their previous labor intensive system.

Join Our Mailing List