Shearers Snacks

Challenge – Shearer’s Snacks, one of the nation’s largest makers of potato chips, tortilla chips and pretzels, needed to retrofit one of their facilities to improve product flow and reduce forklift traffic. The challenge was to move pallets of bagged/boxed chips from the production facility to their storage facility. We needed the ability to handle multiple pallets per minute. The distance to travel was nearly 300 feet. The installation was in a high volume, high traffic area that could not shut down for our install teams. Need:

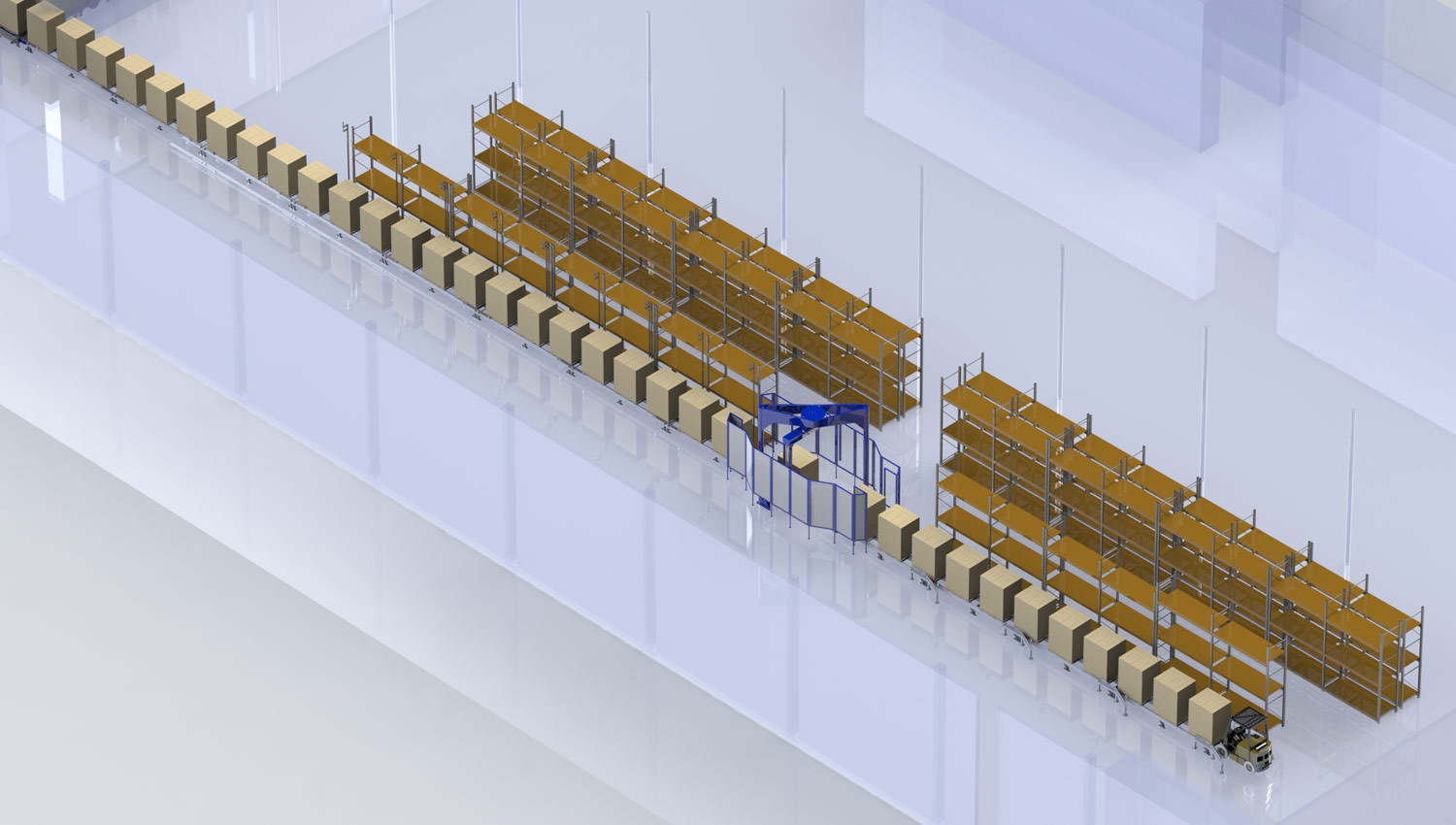

Solution – Byron Automation designed, built and installed nearly 300 feet of “smart” conveyance. With load sensing technology the line would signal the forklift operator when to introduce a new load. Optimized for staging the chain conveyor transported the pallets through a rotary wrapper to a 90 degree chain to roller transfer. Roller conveyor would then accumulate 12 pallets to provide maximum working time for the warehouse. Utilizing the newest Smart Motor technology from Nord Gear, the conveyor motors were all Ethernet controlled.

Join Our Mailing List